Proposed Title: Identifying optimal application rates of urine-based fertilizer for basil grown in climate-controlled aeroponics chambers.

Credits: 30 credits; Level: Advanced

Subject: Technology or Environmental Science

Start: Fall 2019 (flexible)

Background: In the sanitation sector, there is growing recognition that we urgently need to change the way we handle, treat, and recycle human wastes in our environment. At the Swedish University of Agricultural Sciences (SLU), the environmental engineering research group has developed the ‘urine dehydrator’, an exciting new technology that converts liquid human urine into a hygienic, commercial-quality, dry fertiliser. The technology involves two steps, (a) using a urine-diverting toilet at home, to separately collect urine without the faeces; and (b) drying the urine within an alkaline substrate that placed is placed in the urine dehydrator. The out-put is a dry, hygienic, nutrient rich fertilizer. Plant trials in soil have already shown how effective this fertilizer can be. We are theorizing that the biostimulants contained in urine are stabilized during the treatment process.

Now we will investigate the potential of these biostimulants from our urine-based fertilizer. Basil will be grown in Optima Planta’s newly designed climatic controlled aeroponics chamber. By controlling the environment (CO2 concentrations, temperature, light, RH%) while varying the fertilizer type (urine-based fertilizers and conventional fertilizers) and rate of application, we can measure the changes in growth rates, water-usage, CO2 consumption, etc. Fertilizer and plant samples will also be analysed for various compounds (NPK, biostimulants).

Results from this project will significantly contribute towards an ongoing research project funded by the Swedish Research Council called, “Productive on–site sanitation system: new value chain for urine based fertiliser”.

Involved in this project:

- Jenna Senecal, PhD Candidate, Environmental Engineering Group, Department of Energy and Technology (Uppsala), SLU;

- Lennart Sör, Optima Planta Sweden AB, Uppsala

- Prithvi Simha, PhD Candidate, Environmental Engineering Group, Department of Energy and Technology (Uppsala), SLU;

- Martin Weih, Professor, Plant Ecology & Weed Biology Group, Department of Crop Production Ecology (Uppsala), SLU;

- Jean W.H Yong, Professor, Department of Biosystems and Technology (Alrnap), SLU;

- Björn Vinnerås, Assoc. Professor, Environmental Engineering Group, Department of Energy and Technology (Uppsala), SLU;

Interested? Get in touch with us by emailing jenna.senecal@slu.se

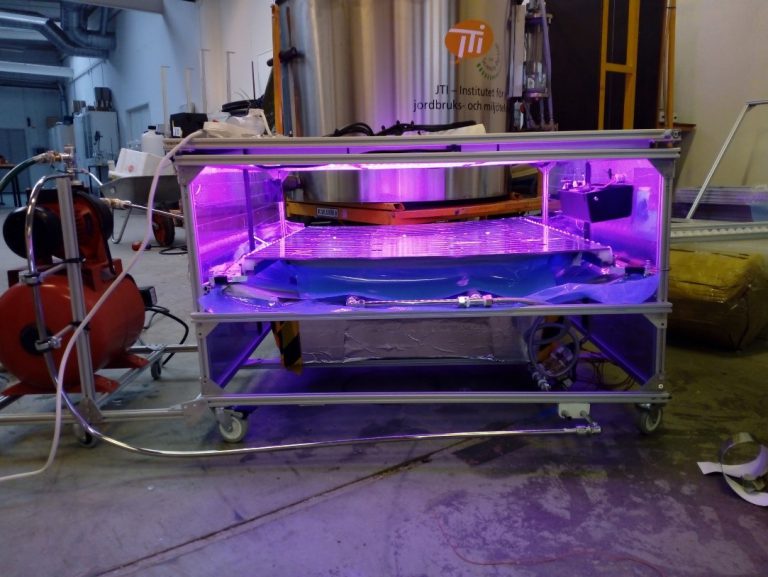

About Optima Planta’s growth module:

It was developed in order to collect data in a closed environment, also using aeroponics. The modules, about 1m³ in size, collects data at a high resolution in real time, enabling statistical analysis with large data sets. Data collected from one growth module is currently 40,000 data points per week as well as a stream of images (1 img/day). The growth modules has a control system which enables the environment to be “locked” within a certain interval i.e. the humidity to be 70-80% relative humidity throughout the growth process or the temperature to be 23-24 degrees celsius etc.

The growth modules are fully automated, no labour is needed during the cultivation of plants, and collects data automatically without any additional data management.

Any number of sensors can be added to the growth module, making the modules customizable depending on the research conducted. Currently, the data collected is carbon dioxide, weight, humidity and temperature, pH and electrical conductivity. Some features are configured before a given experiment, such as spray frequency, pressure and spray length, nutrient composition, light intensity, and type of emitted light.